| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Qingdao Sande Technology Co., LTD

Model Number : OEM

Certification : ISO, DIN, AISI, ASTM, BS, JIS, etc.

Place of Origin : Qingdao, China

MOQ : 1000

Price : $0.5-2

Payment Terms : D/P,T/T,Western Union

Supply Ability : 10000PCS/month

Delivery Time : 30 days

Packaging Details : Wooden case

Material : Stainless steel

attribute : packaging

Surface Treatment : Polishing, Powder Coating, Anodizing

Quality Control : ISO9001,100% inspection before shipping

Capacity : 100,00pcs/Month

Product Material : Carbon steel Boron steel 35mnB

Lead Time : 30-45Days

Packingour Request : Carton box, wooden box

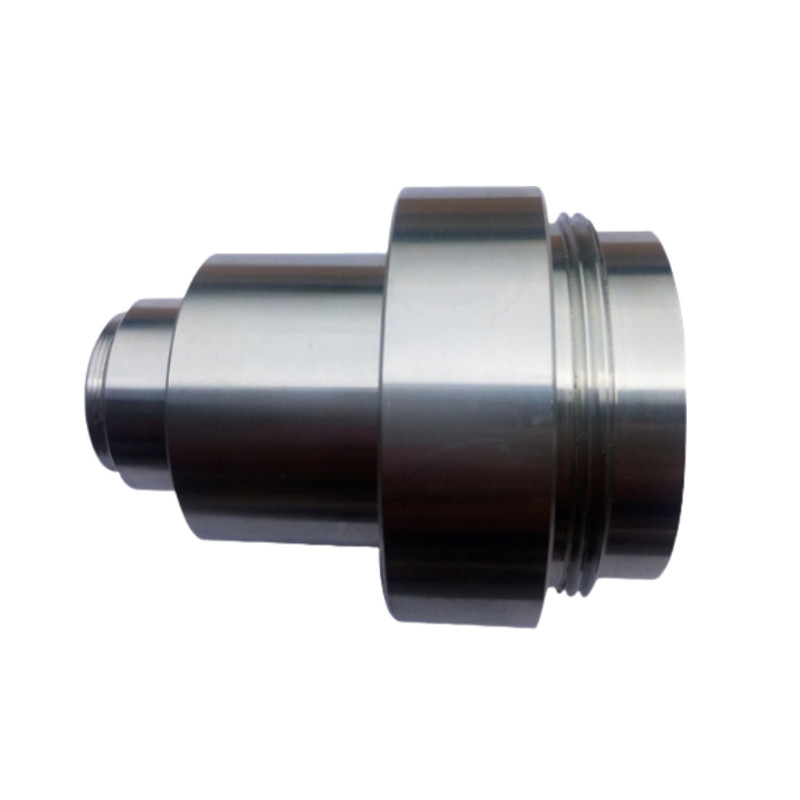

Precision CNC Machining of Stainless Steel Parts: Lathe Nuts and Industrial Accessories

Product Overview

We specialize in high-precision CNC machining of stainless steel lathe nuts, fasteners, and industrial accessories, offering custom OEM manufacturing with strict tolerance control. Our CNC turning and milling services produce durable, corrosion-resistant components for demanding applications across aerospace, automotive, and heavy machinery industries.

Key Features

✔ Material Expertise:

Stainless Steel (303, 304, 316, 17-4PH)

Aluminum, Brass, Titanium (on request)

✔ Precision Machining:

Tolerance: ±0.005mm (±0.0002")

Surface Finish: Ra 0.4–1.6μm (16–63μin)

Thread Standards: Metric, UNC, UNF, BSPP, NPT

✔ Custom Solutions:

Non-standard lathe nuts & threaded fittings

Flanged, hexagonal, or captive nut designs

Anti-vibration & locking features

✔ Secondary Processing:

Passivation & electropolishing

Heat treatment (hardening, stress relief)

Laser engraving for traceability

Product Specifications

| Feature | Description |

|---|---|

| Materials | High-quality stainless steel |

| Machining Process | CNC machining |

| Precision | Tolerance up to ±[insert value] mm |

| Part Types | Lathe nuts, industrial accessories |

| Surface Finish | Custom finishes available (e.g., polished) |

| Application Areas | Aerospace, automotive, electronics, machinery |

| Production Capacity | Up to [insert quantity] units per month |

| Quality Standards | ISO 9001 certified |

| Lead Time | [Insert lead time] days |

Product application

1. CNC Machinery & Tooling Systems

2. Fluid Control Systems

3. Transportation Equipment

4. Industrial Machinery

5. Energy Sector Applications

6. Specialized Applications

FAQ :

1. What types of stainless steel parts do you specialize in?

High-precision lathe nuts (hex, flange, square, captive)

Industrial fasteners and threaded components

Custom CNC-turned and milled parts for machinery

Complex geometries with tight tolerances

2. What materials do you work with?

Stainless Steel: 303, 304, 316, 17-4PH

Aluminum: 6061, 7075

Other Metals: Brass, Titanium (Grade 2/5)

Special alloys available upon request

3. What tolerances can you achieve?

Standard: ±0.01mm (±0.0004")

High Precision: ±0.005mm (±0.0002")

Tighter tolerances available for critical dimensions

4. Do you provide surface finishing options?

Mechanical: Polishing, bead blasting

Chemical: Passivation, electropolishing

Coatings: Nickel plating, black oxide

Marking: Laser engraving for traceability

5. What quality control measures do you have?

ISO 9001 certified processes

100% dimensional inspection

Material certification (MTR)

First article inspection reports (FAIR)

6. What industries do you serve?

CNC machinery and automation

Fluid power systems

Transportation equipment

Energy and industrial applications

7. What certifications do you hold?

ISO 9001:2015

RoHS compliance

Material traceability documentation

Industry-specific certifications available

|

|

Precision CNC Machining Stainless Steel Parts Lathe Nuts And Industrial Accessories Images |